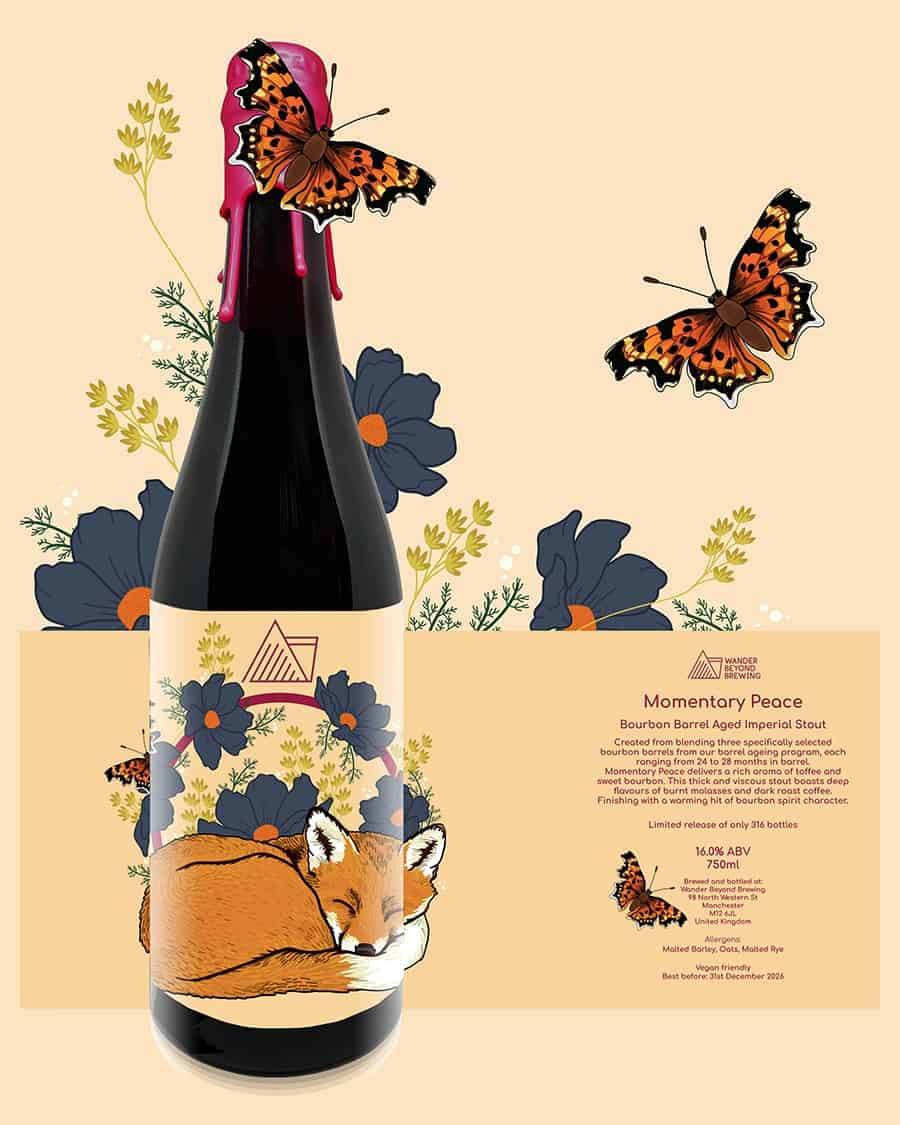

Our Products

Custom labels that make your products stand out.

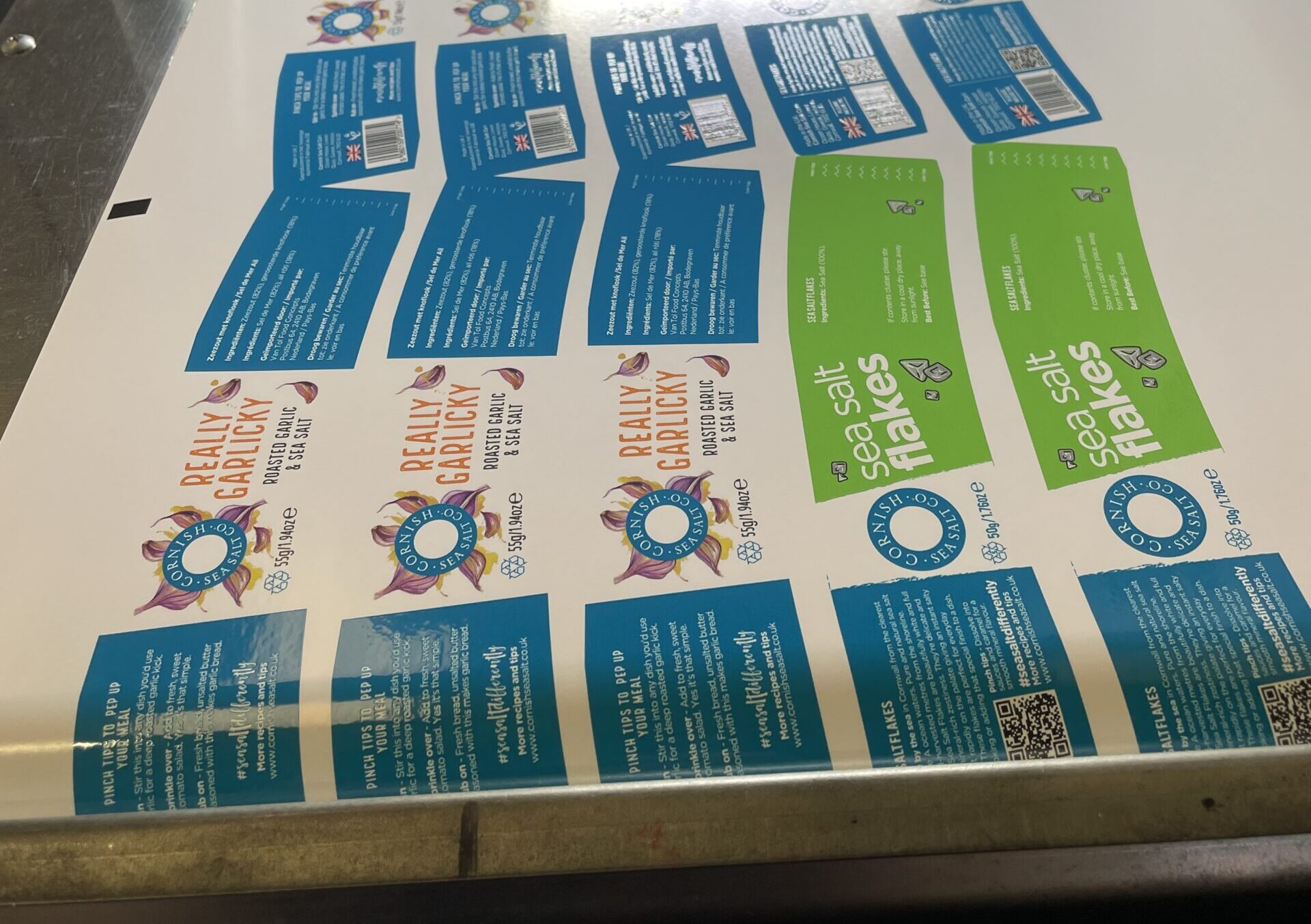

Digital Labels

Photo quality using both digital toner and inkjet printing presses. With no plate costs, Digital printing is ideal for short-to-medium runs across multiple label sorts with the option of printing variable data, barcodes and QR codes, offering flexibility and fast turnarounds.

Materials and Finishes

We offer an almost endless list of materials, including sustainable, kraft, metallic and holographic options with custom finishes. Including specialist finishes, foils, laminates and embossing.

Read MoreFlexo Labels

Great for medium to large volumes of labels. Using high-quality inks, we can print images in up to eight colours and match specific Pantone colours.

Hotfoil and Plain Labels

Hotfoil printing is great for short runs of labels or specialist work, especially for bespoke products such as write-and-seal labels. Plain labels - Custom cut, Direct and Thermal plain labels available on a range of materials.